The Chrysler 300, like all modern vehicles, relies on the OBD2 (On-Board Diagnostics 2) system for diagnostics and emissions testing. A failure to communicate with the OBD2 port can be a frustrating roadblock, especially during a vehicle inspection. This article will address common causes and solutions for Chrysler 300 Obd2 communication failures.

Understanding the Problem: OBD2 Communication Failure

When a Chrysler 300 fails to communicate with an OBD2 scanner, it means the scanner cannot establish a connection with the vehicle’s computer (PCM – Powertrain Control Module). This prevents the retrieval of diagnostic trouble codes (DTCs) and other crucial data. A failed communication can be indicated by messages such as “No Communication,” “Link Error,” or “Unable to Connect.” During an inspection, this issue will result in an automatic fail.

Common Causes of Chrysler 300 OBD2 Issues

Several factors can contribute to a Chrysler 300’s inability to communicate via the OBD2 port:

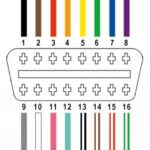

- Dirty or Damaged OBD2 Connector: Corrosion, debris, or bent pins within the connector can disrupt the connection. This is often the easiest problem to fix.

- Blown Fuse: The OBD2 system is typically powered by a specific fuse. A blown fuse will cut off power to the port, preventing communication. Check your owner’s manual for the correct fuse location.

- Wiring Problems: Damaged or loose wiring in the OBD2 circuit, often due to wear and tear or previous repairs, can interrupt the signal flow.

- Faulty PCM: In rare cases, a malfunctioning PCM can be the root cause of the communication failure. This is a more serious issue that requires professional diagnosis.

- Scanner Compatibility: While less common, an incompatible or faulty OBD2 scanner can also lead to communication errors. Trying a different scanner can rule out this possibility.

Troubleshooting Steps

If your Chrysler 300 fails to communicate with an OBD2 scanner, follow these steps to diagnose and resolve the problem:

-

Visual Inspection: Begin by examining the OBD2 connector for any visible damage, loose wires, or signs of corrosion. If you recently replaced the audio amplifier, double-check fuse 18, as it might be shared with the OBD2 system.

-

Connector Cleaning: Use a contact cleaner specifically designed for electrical connections to clean the OBD2 connector pins. A small brush or compressed air can help remove debris.

-

Fuse Check: Consult your owner’s manual to locate the OBD2 system fuse. Inspect the fuse for any signs of damage or breakage. Replace it if necessary.

-

“Key Dance” Test: Perform the “key dance” (turning the ignition key on and off three times) to see if any diagnostic trouble codes are displayed on the instrument panel. While this may not be sufficient for inspection, it can offer clues.

-

Alternative Scanner: Try using a different OBD2 scanner to rule out scanner compatibility issues. Borrow one from a friend or visit an auto parts store that offers free code reading.

-

Professional Diagnosis: If the problem persists after these steps, it’s recommended to seek professional help from a qualified automotive technician. They can perform more advanced diagnostics to pinpoint the exact cause of the communication failure.

Conclusion: Getting Your Chrysler 300 Back on the Road

A Chrysler 300 OBD2 communication failure can stem from simple issues like dirty connectors or more complex problems like wiring or PCM malfunctions. By following the troubleshooting steps outlined in this article, you can often identify and resolve the issue yourself. However, if the problem persists, seeking professional assistance is crucial to ensure a proper diagnosis and repair, allowing your Chrysler 300 to pass inspection and return to the road safely.