OBD2 (On-Board Diagnostics, generation two) revolutionized automotive diagnostics 20 years ago. While generic OBD2 scan tools are inexpensive and powerful diagnostic starting points, many technicians still underutilize the valuable data they provide, particularly Obd2 Fuel Trim. This article delves into the importance of baselining fuel trim data for efficient and accurate diagnosis.

Baselining OBD2 Fuel Trim: A Four-Step Process

Understanding fuel trim is crucial for diagnosing air/fuel mixture issues. Fuel trim refers to the adjustments made by the engine control module (ECM) to maintain the stoichiometric ratio (the ideal air/fuel mixture for optimal combustion). There are two types: Short Term Fuel Trim (STFT) makes immediate adjustments, while Long Term Fuel Trim (LTFT) applies learned corrections over time. Here’s a simple four-step process to baseline fuel trim:

- Connect: Connect an OBD2 scan tool, preferably one with recording capabilities, to the vehicle’s diagnostic port.

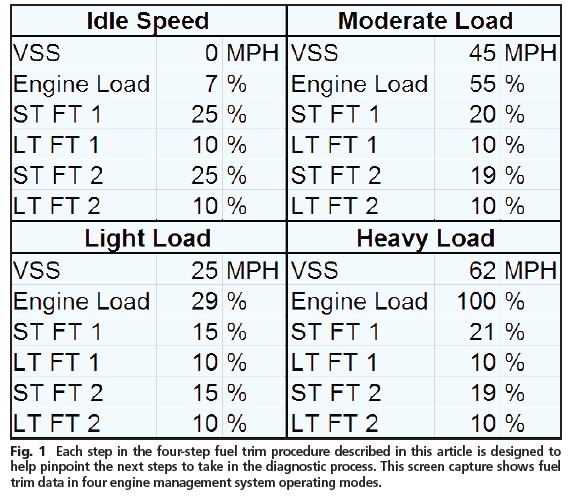

- Monitor and Record: Monitor and record both STFT and LTFT values across four common operating ranges: idle, light load (20-30 mph), moderate load (40-50 mph), and heavy load (60-70 mph).

- Analyze: Analyze the recorded data, looking for patterns and deviations from normal values. Positive fuel trim values indicate a lean condition (too much air), while negative values indicate a rich condition (too much fuel). Consistent deviations across all operating ranges often point to a systemic issue.

- Diagnose: Use the analyzed data to narrow down the potential causes and guide further diagnostic steps. Fuel trim data helps pinpoint the source of the problem, whether it’s a vacuum leak, faulty MAF sensor, fuel delivery issue, or other related components.

Figure 1: Example of fuel trim data indicating a lean condition across all operating ranges.

Interpreting OBD2 Fuel Trim Data

Consider a scenario with diagnostic trouble codes (DTCs) P0171 (Bank 1 System Lean) and P0174 (Bank 2 System Lean). Numerous potential causes exist, including vacuum leaks, fuel pump issues, or a faulty mass airflow (MAF) sensor.

Figure 2: Typical gasoline direct injection (GDI) system layout with relevant sensors and actuators.

Analyzing fuel trim data helps differentiate between these possibilities. High positive fuel trim values at idle that decrease at higher speeds might suggest a vacuum leak. Consistently high positive fuel trim across all ranges, as in Figure 1, points towards a systemic issue like a faulty MAF sensor or low fuel pressure.

Figure 3: Fuel trim values typically associated with an intake air leak.

OBD2 Fuel Trim and Component Diagnosis

Understanding how specific components influence fuel trim is vital. For instance, a malfunctioning purge valve, which controls the flow of fuel vapors from the charcoal canister, primarily affects fuel trim at idle.

Figure 4: Example of a vacuum leak’s impact on Short Term Fuel Trim (STFT).

A failing fuel pump might show slightly elevated fuel trim at idle, worsening with increasing load. A faulty MAF sensor, crucial for determining airflow into the engine, will often result in consistently incorrect fuel trim across all operating ranges.

Figure 5: MAF sensor data indicating underestimation of airflow.

Conclusion: OBD2 Fuel Trim as a Diagnostic Cornerstone

OBD2 fuel trim provides invaluable insights into engine performance and air/fuel mixture control. Utilizing the four-step process outlined above, technicians can effectively leverage this data to streamline diagnostics, pinpoint the root cause of issues, and ensure efficient repairs. Mastering the interpretation of OBD2 fuel trim remains a cornerstone of modern automotive diagnostics.