OBD2 (On-Board Diagnostics, version 2) is a standardized system that allows external devices to access a vehicle’s diagnostic information. Communication with an OBD2 system relies on specific serial commands, often referred to as Obd2 Serial Commands. This article delves into the structure and functionality of these commands, providing a foundational understanding of how to interact with a vehicle’s onboard computer.

Understanding these commands is crucial for anyone working with car diagnostics, from professional mechanics to DIY enthusiasts. By sending the correct commands, you can retrieve valuable data about the vehicle’s performance, identify potential issues, and even clear diagnostic trouble codes.

Structure of OBD2 Serial Commands

OBD2 serial commands are hexadecimal codes transmitted as ASCII characters. These commands typically consist of two or more pairs of hexadecimal numbers.

- Mode: The first hexadecimal pair specifies the diagnostic mode. There are ten standard OBD2 modes, each serving a specific purpose such as retrieving current data, freeze frame data, or diagnostic trouble codes.

- PID (Parameter ID): The subsequent hexadecimal pairs represent the specific parameter you want to read within the chosen mode. PIDs define the type of data being requested, such as engine RPM, coolant temperature, or vehicle speed.

OBD2 Modes and their Functions

The ten OBD2 modes offer a comprehensive range of diagnostic functionalities:

| Mode | Description |

|---|---|

| 01 | Current Data (Real-time sensor values) |

| 02 | Freeze Frame Data (Snapshot of data at the time of a fault) |

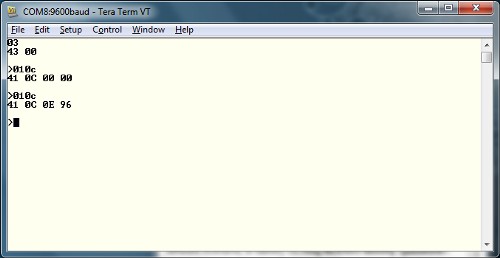

| 03 | Diagnostic Trouble Codes (Stored fault codes) |

| 04 | Clear Trouble Codes (Erase stored fault codes) |

| 05 | Test Results/Oxygen Sensors (Oxygen sensor data) |

| 06 | Test Results/Non-Continuous Testing (Results of specific tests) |

| 07 | Show Pending Trouble Codes (Codes that haven’t yet triggered the MIL) |

| 08 | Special Control Mode (Manufacturer-specific tests) |

| 09 | Request Vehicle Information (VIN, calibration data, etc.) |

| 0A | Request Permanent Trouble Codes (Codes permanently stored after repairs) |

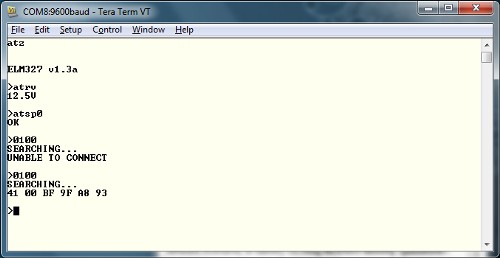

Decoding OBD2 Responses

When an OBD2 command is sent, the system responds with a data string also formatted in hexadecimal. The response structure follows a consistent pattern:

- Mode Echo: The first byte echoes back the requested mode, incremented by 0x40 (e.g., a request for Mode 01 results in a response starting with 0x41).

- PID Echo: The second byte echoes back the requested PID.

- Data Bytes: The remaining bytes contain the actual data corresponding to the requested PID. This data often requires further interpretation based on the specific PID. For example, some values are represented as multiples or fractions of the actual measurement.

Essential OBD2 Serial Commands

A fundamental command is Mode 01, PID 00. This command requests a list of supported PIDs for Mode 01, providing insight into the data available from the vehicle.

Another frequently used command is Mode 01, PID 0C, which retrieves the engine RPM. The response data needs to be converted from hexadecimal to decimal and then divided by 4 to obtain the actual RPM value.

Resources for Further Exploration

The ELM327 datasheet offers a comprehensive list of OBD2 PIDs and their corresponding data interpretations. Wikipedia also provides detailed information on OBD-II PIDs. Remember that some vehicle manufacturers may implement proprietary PIDs, so consulting vehicle-specific documentation is essential for a complete understanding.

By mastering OBD2 serial commands, you gain a powerful tool for diagnosing and understanding vehicle performance, enabling you to address issues efficiently and effectively.